Are you in the market for an industrial scale? Whether you’re running a manufacturing plant, warehouse, or laboratory, having the right scale is crucial to your operations. With so many options available on the market, it can be overwhelming to choose the best one for your needs. That’s where consumer reports come in handy! In this blog post, we’ll go over everything you need to know about industrial scales – from how they work and their different types to what factors to consider before making a purchase. We’ll also explore the benefits of using an industrial scale and provide tips for setting one up. So sit back and let us guide you through finding the best industrial scale for your business!

Top 10 Industrial Scale

*Note: Score is based on our AI score (Editor’s choice and rating).

What Is Industrial Scale?

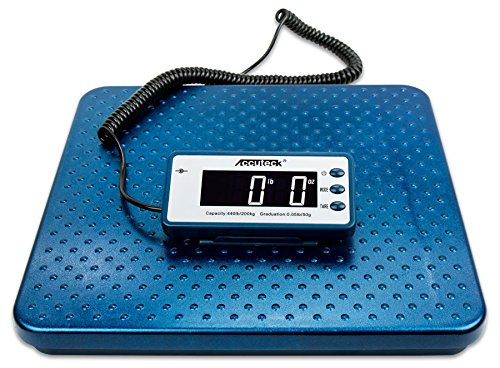

An industrial scale is a heavy-duty weighing device used to weigh large objects or quantities of materials. Unlike regular household scales that are designed for personal use, an industrial scale is built to withstand the rigors of commercial and industrial settings. Industrial scales come in different sizes and types, depending on their intended use.

Industrial scales typically have higher weight capacity than household scales and can handle loads ranging from several hundred pounds to thousands of pounds. They’re commonly used in industries such as manufacturing, agriculture, logistics, and chemical processing.

Many industrial scales have additional features like platform ramps for easy loading, digital displays for accurate readings, and data recording capabilities for record-keeping purposes. Some even come equipped with software that enables users to track inventory levels or monitor production output.

An industrial scale plays a vital role in maintaining the efficiency and accuracy of operations across various industries. Whether you need to weigh raw materials before production or check the weight of finished products before shipping them out, investing in a reliable industrial scale can help streamline your business processes while saving time and money in the long run.

How Does Industrial Scale Work?

An industrial scale is a device used to measure the weight of objects in an industrial setting. It operates by using load cells, which detect and convert the weight of an object into an electrical signal. This signal is then sent to a computer or display unit that shows the weight in numerical form.

Load cells are typically made up of four strain gauges arranged in a Wheatstone bridge configuration, which allows for precise measurement and accuracy. When an object is placed on top of the scale platform, it applies force onto each individual strain gauge causing them to change resistance values slightly.

These changes in resistance values are detected by the load cell’s electronics and converted into an electrical signal proportional to the amount of force applied on each gauge. The signals from all four strain gauges are combined and processed by the electronic circuitry within the load cell resulting in a final output signal representing the total weight applied on top of it.

Industrial scales come equipped with different types of displays such as digital or analog, depending upon their application requirements. Some models also feature additional functions like tare (to remove container weights), counting (to count items quickly), accumulation (to sum multiple weights) etc., making them versatile for use across various industries.

Industrial scales work based on measuring force exerted upon their platforms through sensitive load cells that convert this physical input into accurate measurements displayed electronically or mechanically.

The Different Types of Industrial Scale

There are different types of industrial scales, each with its own unique features and functions. The type of scale you choose will depend on your specific needs and application. Here are some common types of industrial scales:

1. Platform Scales: These are large scales that can accommodate heavy-duty weighing tasks such as pallets, crates, and other oversized items.

2. Counting Scales: These scales help in counting large quantities of small parts such as screws or bolts.

3. Bench Scales: These compact scales provide accurate measurements for smaller objects like packages or containers.

4. Crane Scales: Ideal for measuring the weight of goods being lifted by cranes or hoists, these heavy-duty devices have high load capacities.

5. Floor Scales: As the name implies, these larger-sized models sit directly on the floor to weigh bulkier items such as machinery or equipment.

Each type is designed to fulfill a specific purpose in an industrial setting, making it important to select one that matches your requirements precisely while providing consistent results every time they’re used

Factors to Consider Before Buying Industrial Scale

When looking to purchase an industrial scale, there are several important factors that you should consider before making your decision. First and foremost, it’s important to determine the maximum weight capacity that you will need for your specific application. This will ensure that the scale can handle the weight of your products or materials without causing damage or inaccuracies.

Another key factor to consider is accuracy. Industrial scales come with varying levels of precision, so it’s important to choose one that provides the level of accuracy required for your needs. Additionally, consider whether you require a digital display or prefer traditional analog readouts.

You should also think about portability and durability when choosing an industrial scale. Will the scale need to be moved frequently between locations? If so, a lightweight and portable option may be best suited for your needs. Alternatively, if you require a more heavy-duty solution for harsh environments or frequent use, then a rugged model would be ideal.

Other factors worth considering include connectivity options (such as Wi-Fi or Bluetooth), power source (battery-powered vs electric), and ease of calibration/maintenance.

By taking into account all these different factors before purchasing an industrial scale, you’ll be able to find one that meets all your requirements and ensures accurate weighing every time!

Benefits of Using Industrial Scale

Using an industrial scale can provide numerous benefits for various industries. One of the primary advantages is accuracy in measurements, especially when dealing with large and heavy materials. Industrial scales are designed to weigh heavy loads that regular scales cannot handle accurately.

Another benefit of using industrial scales is their durability and efficiency. These types of scales are built to withstand harsh working conditions such as extreme temperatures, moisture, and dust particles. They can also endure a significant amount of wear and tear which makes them long-lasting investments.

Moreover, industrial scales come in different sizes suitable for specific applications like counting parts or weighing liquids accurately. The versatility of these machines allows businesses to streamline their operations effectively while reducing human errors that could lead to losses.

Industrial scales also promote safety at work by minimizing the risk of accidents during loading or unloading processes since they have features like overload protection systems that prevent overloading beyond capacity limits.

Investing in an industrial scale leads to increased productivity, improved accuracy in measurement results, better inventory control management leading to cost savings on material handling expenses caused by wrong shipment weights or inaccurate inventory counts.

The Pros and Cons of Industrial Scale

Industrial scales come with a set of advantages and disadvantages that can affect your decision to invest in one. Let’s take a closer look at the pros and cons of industrial scale:

Pros:

An industrial scale provides accurate measurements necessary for consistent production output. It helps you maintain quality control by ensuring that every product is weighed correctly. It saves time as it can measure larger quantities in less time compared to manual weighing methods. It improves safety by reducing the risk of injuries from manually lifting large items.

Cons:

One downside of using an industrial scale is its cost, which can be high depending on the type and capacity you need. Maintenance requirements also add extra costs over time. The weight capacity limits may also restrict certain operations or products that require heavier loads.

Understanding the advantages and disadvantages of using an industrial scale will help you make an informed decision when considering purchasing one for your business needs.

Tips For Setting Up Your Industrial Scale

When it comes to setting up an industrial scale, there are a few important tips that can help you make sure the process goes smoothly and the scale functions properly.

First, ensure that your scale is installed on a level surface. This will prevent any inaccuracies in measurement due to uneven weight distribution.

Next, make sure you calibrate your scale regularly. This ensures that the readings are accurate and reliable over time.

It’s also important to keep your industrial scale clean. Regular cleaning prevents dust buildup and keeps the weighing mechanism functioning optimally.

Consider investing in software or apps that allow for remote monitoring of your industrial scale. This can save time and increase efficiency by allowing for quick analysis of data from wherever you are.

By following these tips, you’ll be able to set up and maintain an industrial-scale with ease!

FAQs

FAQs or frequently asked questions are an essential part of any buying decision, especially when it comes to industrial scales. Here are some common questions consumers ask before purchasing an industrial scale.

Q: What type of industrial scale should I buy?

A: The type of industrial scale you need depends on your application and industry. Platform scales are ideal for weighing large items, while counting scales are perfect for measuring small parts.

Q: Can I use my industrial scale for legal trade purposes?

A: Not all industrial scales can be used for legal trade purposes. If you need a scale that meets regulatory requirements, look for one that is NTEP approved.

Q: How accurate is an industrial scale?

A: The accuracy of an industrial scale varies depending on the model and manufacturer. Look at the specifications provided by the manufacturer to determine how accurate their product is.

Q: Do I need special training to operate an industrial scale?

A: While most modern scales are user-friendly, it’s always best to read through the instruction manual before using them. If you’re unsure about anything, contact the seller or manufacturer for assistance.

By understanding these FAQs before purchasing an Industrial Scale, users can make informed decisions based on their needs and preferences without getting overwhelmed with technical details or features they don’t require.

Conclusion

Buying an industrial scale requires careful consideration of various factors such as capacity, accuracy, durability, and functionality. It’s important to choose the right type of industrial scale that suits your specific needs and budget.

With so many options available in the market, it can be overwhelming to make a decision. That’s why consumer reports are essential tools for anyone looking to purchase an industrial scale. These reports provide unbiased reviews from people who have used different types of scales.

By following the tips outlined in this article and consulting consumer reports, you can find the best industrial scale that meets your requirements. Whether you’re running a small business or a large manufacturing plant, having an accurate and reliable measurement system is crucial for success.

I’m Ella Andrews, owner of the website https://bestconsumerstips.com/

I give you valuable information about good products to help you choose the best product.